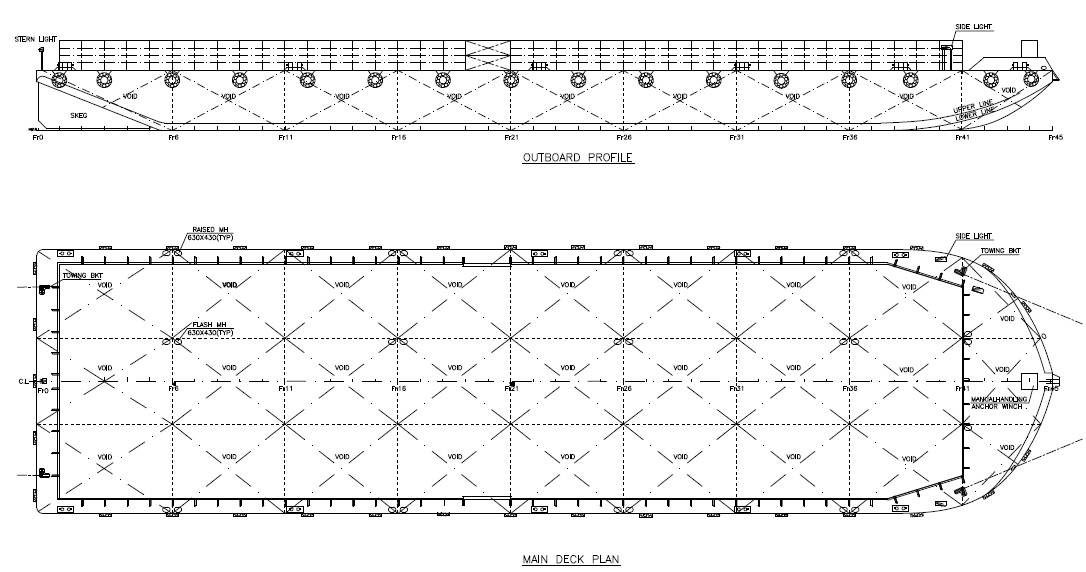

Plan Drawing Transverse Frame Barges Material Detail

1. GENERAL DESCRIPTION

The vessel is an unmanned dump barge suitably equipped for carrying deck cargo for unrestricted services. The barge is all welded steel construction. Information technology has flush deck and twin skegs. The primary hull is divided by 8 (8) transverse West.T. bulkheads and two (2) longitudinal Westward.T. bulkheads into 20-7 (27) compartments.

2. PRINCIPAL PARTICULARS

Length: 82.30 1000 (270'-0")

Beam: 21.forty G (70'-0")

Depth: 4.90 Chiliad (16'-0")

Frame spacing: 1830 MM

Draft moulded: three.80 G (approx.)

Deadweight: 5500T (approx.)

Deck loading: 7 Tonnes/M2

3. Classification

The vessel is designed suitable for registration as a cargo clomp and constructed in accordance with the latest rules and regulations of ABS for unrestricted services and to their special Survey to hull for Form for Unmanned Deck Barge. Notation: ABS +A1 Deck Barge.

4. CERTIFICATES

The following certificates volition be supplied to the Possessor at the fourth dimension of delivery of the vessel:

(a) Architect's Document

(b) Temporary International (1969) Tonnage Document issued past ABS

(c) Acting Course Certificate issued by ABS

(d) Conditional Load Line Document by ABS

(due east) Cargo Ship Safe Construction Certificate issued by ABS

(f) Anti fouling certificate by ABS

5. MATERIALS & WORKMANSHIP

All materials and workmanship volition be of the highest quality, with all steel plates, sections,hull forging and castings met with ABS Classification requirements and approval.

6. WELDING

The vessel will be welded synthetic. Welding is to be carried out in accord with the Classification'southward requirements and to the attending Surveyor's Satisfaction.

7. TEST

Prior to the delivery, the hull and other fittings etc. to be thoroughly tested to the satisfaction of the Classification's attending Surveyor.

8. STABILITY BOOKLET

The stability booklet is to be prepared and supplied by the builder based on the estimated lightship weight or the results from lightship Survey if and when required past the Classification.

9. SCANTLINGS:

Plating

Deck: 12.0mm

Lesser: 12.0mm

Sides: 12.0mm

Longitudinal Bulkhead: 8.0mm

Transverse Bulkhead: 8.0mm

Longitudinal

Deck Longitudinal: 125x80x7mm O.A./125x80x7mm O.A. (Deck beam)

Bottom Longitudinal: 125x80x8mm O.A./ 140x90x8mm O.A. (Bottom beam)

Side Longitudinal: 125x80x7 mm O.A./ 125x80x8 mm O.A.(FR.36~Fore)

Longitudinal Bhd. Strong. 100x80x6 mm O.A./100x63x6 mm O.A.(FR.36~Fore)

Transv.Bhd.Strong. 100x80x6mm O.A. /100x63x6 mm O.A

Transv.Bhd.Stringers 250x8+75 flanged plate

Transverse/ Webs (Approx. subject to changes)

Deck transverse:

450x10+100mm flanged plate

350x8+75mm flanged plate

Bottom Transverse:

400x10+100mm flanged plate

350x8+75mm flanged plate

Side Transverse

400x8+75mm flanged plate

450x8+75mm flanged plate

Deck.Girder

450x8+100mm flanged plate (Fr.0~36)

350x8+75mm flanged plate(Fr.36~fore)

Lesser Girder:

400x8+100mm flanged plate (Fr.0~36)

350x8+75mm flanged plate (Fr.36~fore)

Long. Bhd. WEB.:

400x8+75mm flanged plate

Transv.Bhd.Spider web.

450x10+100mm flanged plate(Fr.0~36)

400x8+75mm flanged plate(Fr.36~fore)

Stanchions

Vertical: 250x10+250 FLG. (Fr.0~36)

Vertical: 150X150X12mm O.A. (Fr.36~ fore)

Diagonals: 140x140x10mm O.A.

Bilges chine ?50 R.B.

10. DECK FITTINGS

(a) Sideboard L73.2m x B19.00m x H2.4m

Plate 8mm

Longitudinal L100x75x7

Vertical web 10mm flanged

(b) One (1) 1290kg stockless bower anchor with 36m x 28mm diameter wire rope.

(c) I (ane) diesel fuel operated winch of 10ton pull to exist provided.

(d) Affluent type watertight manholes of 630x430 on primary deck are to be provided for heart compartment and heighten type watertight manholes of 600x400 are to be provided for side compartment. Studs, washer and nuts are to exist stainless steel.

(east) xx-seven (27) vertical steel ladders for access to nether deck voids.

(f) Four (four) towing brackets to exist fitted on bow and stern of chief deck, ii for main towing and ii for emergency tow.

(one thousand) Four (4) sets of chaffing chain, 2 for main towing and two for emergency tow.

(h) Iv (four) 55t shackle

(i) Ten (x) mooring bollards of 12'' NB sch lxxx pipe are to exist fitted on chief deck.

(j) Small lags for lashing of portable type fenders to be fitted on deck.

11. NAME AND DRAFT MARKS

The name of the barge is to be welded and painted on the bow port and starboard, the name and port of registry of the barge are to be welded on and painted on the stern. All messages are to be not less than 300mm in height. Port of registry is to be not less than

12. PAINTING

All steel plates/steel material is to be dust blasted to SA2.5 on both sides of the steel plates and all circular on all other steel materials and cleaned to equally high a standard as possible in order to remove all the dust and mill scale prior to painting with 1 (1) coat of marine primer. All steel surfaces are to be complimentary from grease and costless from moisture before priming coats are applied. All coats are to exist thoroughly dry earlier further coats are applied on top.

13. CATHODIC PROTECTION

Lx (lx) zinc anodes are to exist fitted to protect the external hull below the waterline against corrosion.

xiv. Drawings

On completion, three (iii) sets of the following hard prints as approved past the Nomenclature are to be supplied: -

- Lines programme

- General Arrangement

- Construction construction Drawings

- Welding Schedule

- Skeg Detail

- Sideboard particular

- Barrier detail

- Stability Booklet

The details of all vessels are offered in expert organized religion only we cannot guarantee or warrant the accurateness of this data nor warrant the condition of the vessel. Any buyer should instruct their agents, or their surveyors, to investigate such details as the heir-apparent desires validated. This vessel is offered subject to sale, toll change, location or withdrawal without notice.

Source: https://www.seaboats.net/new-build-82.3m-deck-cargo-barge-1360230

0 Response to "Plan Drawing Transverse Frame Barges Material Detail"

Publicar un comentario